Monday 26th November 2018

The forecast this week is for heavy rain at times – but this morning is relatively bright – if a little chilly!

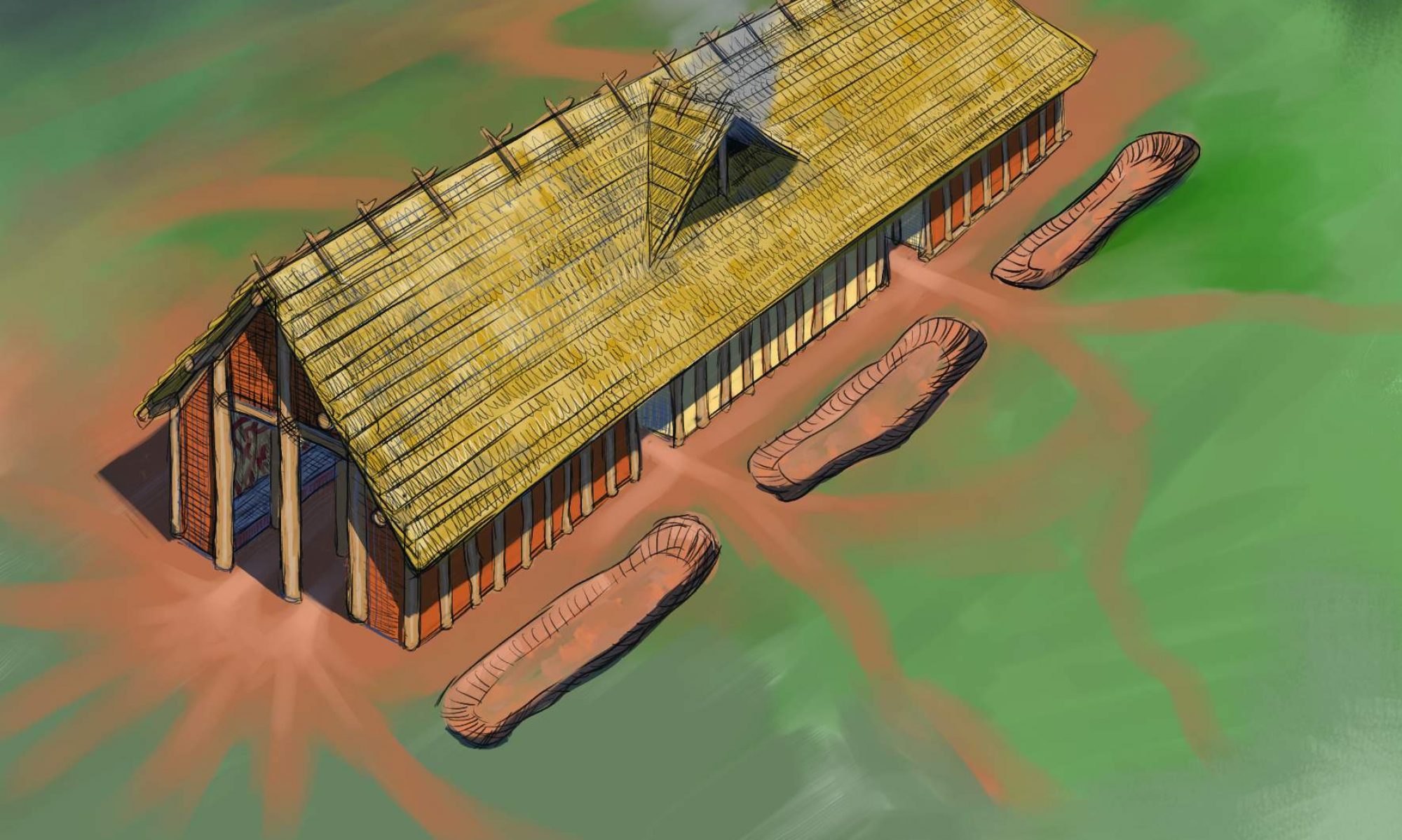

We have set aside this week to hopefully finish the roof. The thatched ridge will form the water tight cap that keeps the weather out of the building. There are any number of ways of thatching a ridge, and a variety of materials suited to the task (depending on the method chosen). This roof will employ the simplest version of all. In the modern world we are familiar with the sight of beautifully ornate thatched ridges on roofs. Historically this seems to be a very recent phenomenon – illustrated by paintings and early photographs where early butted ridges become ornately decorated in the Victorian period. What is clear is that any number of thatching methods exist that are founded on local tradition that often stems from the use of particular local materials and their specific properties. Our roof is employing a simple ridge that utilises our most abundant material (in this case reed). It may well be the case that as this ridge version degrades, other materials may be tested that are also on the island such as sedge and bracken.

As with all of our new construction stages, the initial learning curve is very steep! Today we tested the process of forming a ridge using teams on both sides of the roof. We found quickly that it is a task that requires fewer people to do well (one on each side and one tying beneath). The process involves securing an inverted (thick end at the top of the roof) bundle on the leeward side of the roof and dressing its butt end to the same slope as the previous layer on the windward side. This is then covered by a bundle on the windward side and both sways lashed through the roof – beneath the internal timber ridge. This effectively squeezes the two sways together and – with the thatch acting as a wedge, prevents the ridge from slipping off.

Tuesday 27th November 2018

Our first real day of rain on the project for months and months! The site is wet and the building interior is extremely dim. We still have most of the north side daubing to complete too, so we need to be careful to allow in as much light as possible on days like these.

One positive is that we can now see the advantage of the daub “robber trenches” as drains. The water from the roof is dripping into these perfectly and taking the water away from the interior floor level and post holes.

Inevitably work progresses more slowly in foul weather, but this morning we are trying to pass on our lessons from yesterdays ridge thatching to new teams of volunteers. The aim is to have this knowledge in more than three brains so work can continue when we have three people on site.

The ridge is progressing and our intention is to finish the ridge this week if the weather allows!

Daubing is in full swing with teams working on the south side of the building. We are also clearing around the building to make way for schools who are hoping to come and daub the building tomorrow.

Wednesday 28th November 2018

After heavy rain last night and high winds forecast for today, the pressure is on to complete the ridge this week. We have settled into something like a routine with the method. Three people working closely from both sides of the roof and beneath.

Today also saw the arrival of 4 schools to help with our daubing mission. It was great to see so many enthusiastic and excited faces getting stuck into the job. It is always interesting to see how quickly children adapt to new situations and this was no different. After an initial briefing, the teams of year 3 and year 6 children set about their work with gusto. We roped off the ladder areas inside and out and from my position in the heavens I could see how much they all really enjoyed the experience of contributing to something that is permanent. There is no better way of learning about the past than actually doing it!

Thursday 29th November 2018

After a night of gales and heavy rain, work continues on the final six metre section of ridge. Nothing was moved on the roof by the wind last night which conforms the quality of our volunteer thatching. Today we have more schools visiting to push on with the daubing of the remaining walls.

Daubing is another one of those jobs that on the face of it seems easy and straight forward. Its just a case of throwing some mud onto the walls right? The reality is very different and once again teaches us the difference between understanding the process of doing something and the skills and refinement required to do that thing well and beautifully. Daub making is a skill. It requires an understanding of the local raw material (earth or clay) and it properties. It requires the understanding of how much or little fibre needs to be added to reduce its shrinkage when it dries on a wall. The amount of water added to the dry daub is a critical factor to success – too much and it becomes impossible to use and will shrink, too little and its is impossible to use, won’t bind with daub through the wattle panel and simply won’t stick to the wall. The application of the daub also requires skill. Working it in the right way, blending and merging it, applying at the right thickness, and of course the standard of finish, are all elements where the artisan has the capability of making a beautiful and functional wall.

All of this skill and knowledge only comes with the act of actually doing it of course. The more of this “simple” task we do, the more we realise it is anything but simple to achieve fine results!

Friday 18th November 2018

Yesterday – with minutes to spare before the light failed, we managed to place the final bundles of thatch on the ridge! What a great achievement by the whole team. Looking back at the sheer hours and effort that have gone into this roof, its slightly strange to think its finished!

Today, we are making some final touches and dressing the ridge to shape. The smoke hole area of the roof has been defined and lashed using various methods to keep the thatch in place and to allow the hole to be kept open if we decide.

The roof has taken 1200 bundles of reed and many metres of cordage to complete. It is only one possible method of thatching a roof and has raised various issues during its construction that should be considered.

What is clear is the amount of experience and skill our volunteers have learnt on this project. They are now more than capable of problem solving with thatching materials and repairing when the roof begins to age. It has been the most epic phase of the construction so far – requiring hundreds of hours on ladders by dedicated and weather resistant people.

I take my hat off to you all for such a wonderful achievement – and doesn’t it look stunning!!